Plastic PE 3D Geocell Ultrasonic Welding Machine

Package Size 3600.00cm * 280.00cm * 270.00cm Package Gross Weight 26000.000kg Plastic Geocell Ultrasonic Welding Machine;

Basic Info.

| Model NO. | JS-TGGS120 |

| Board Layers | Single Plate |

| Screw No. | Single-screw |

| Automation | Automatic |

| Computerized | Computerized |

| Certification | CE, ISO9001:2008, QS |

| Customized | Customized |

| Condition | New |

| Delivery Time | 75 Working Days |

| Welding Heads | 1 - 30 Pieces |

| Maintance | Easy |

| Operators | 3-4 Person/Shift |

| Geocell Height | 75, 110, 150, 200, 330mm |

| Sheet Extruder | 120/33 |

| Welding Space | 150-330mm |

| Transport Package | by Film, Cases, Pallets |

| Specification | 15-22 welding heads |

| Trademark | JUNSHENG |

| Origin | Jiaxing, China |

| HS Code | 84778000 |

| Production Capacity | 20 Sets/Month |

Packaging & Delivery

Package Size 3600.00cm * 280.00cm * 270.00cm Package Gross Weight 26000.000kgProduct Description

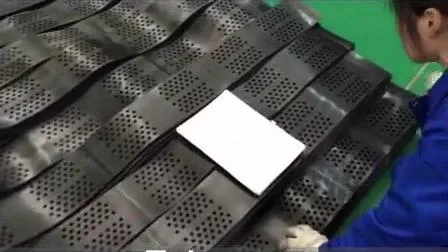

Plastic Geocell Ultrasonic Welding Machine making PE 3D geocell Plastic Geocell Sheet Extrusion and Ultrasonic Welding MachineIt's composed by 2 step machines:1st - plastic sheet machine (another extrusion machine, work together)2nd - ultrasonic welding machinePlastic Sheet Machine models (another extrusion machine, work together):- 90mm single screw extruder- 120mm single screw extruder- Online punch system- Online split unit or winderUltrasonic Welding Machine:- Automatic or semi-automatic- Welding heads: 1-22 heads, according to different requirementsPlastic Geocell Production LineBrief Introduction:1.Junsheng plastic geocell production line can produce the plastic geocell with thickness from 0.8 to 3mm,smooth or embossing surface, with holes or without holes.2.Geocell System can be filled with a wide range of material: aggregate, concrete, sand, soil , etc.3.Geocell is widely used for soil stabilization; to help improve the performance of standard constructionmaterials and erosion-control treatments. So, it's mainly used in fields of erosion control, load support,slope protection, channel protection, retaining wall, ground stabilization and slope protection applications.

Full-automatic Geocell Welding Machine Brief Introduction: 1.PLC control and imported piezoelectric ceramic transducer, output is highly and stability;2.Floating feeding bracket, to keep operating height (don't need operator bend down), operation ismore easy;3.Independent units (frame, generator, retaining clip etc.), the welding pitch will be easy to be adjusted;4.New type welding horn structure, life time is longer, welding strengthen is better;5.The distance between center of horn and frame is reduced, the equipment's rigidity is better;6.Max. height of geocell can reach to 300 mm;7.When width of strip less than half of max. geocell height, the 2 strips can be welded at the sametime,efficiency is double.

You may also like

Send inquiry

Send now